Railway

Optimizing Fuel Efficiency for Rail Transport

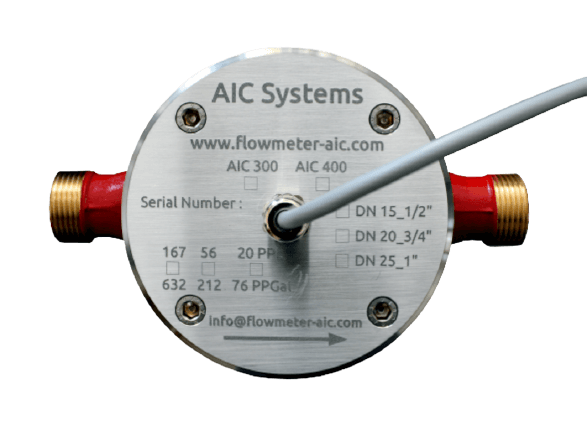

Fuel consumption is a major cost factor in railway operations. AIC’s railway fuel flow meter provides accurate fuel measurement, helping railway companies optimize efficiency and reduce operational expenses. With precise monitoring, operators can train engineers in energy-saving driving techniques and improve fuel economy.

In the case of a diesel locomotive, fuel consumption must be measured and displayed. Because of the harsh operating environment of the railway, measuring fuel consumption is metrologically a greater challenge than power measurement in an electric locomotive.

Reliable Fuel Flow Monitoring for Diesel Locomotives

Diesel locomotives operate under extreme conditions. AIC’s railway flow meter ensures accurate measurement in high-vibration environments, providing real-time data to support train fuel monitoring.

to operate than the same distance on the plain.

Our flowmeters can record fuel consumption values over long periods of time. The measured values are transmitted to the operator‘s electronic system via appropriate interfaces.

Why Choose AIC Fuel Flow Meters for Railways?

High Precision – Advanced fuel flow meter for railway technology ensures accuracy in all operating conditions.

Cost Efficiency – Helps optimize fuel usage, reducing waste and improving profitability.

Durability – Built for harsh railway environments, ensuring long-lasting performance.

In this operating mode, utmost measurement precision of the individual flowmeters is important, to obtain good system measurement precision.

Fuel Flow Measurement for Different Railway Operations

For Passenger Trains: Monitoring Fuel Usage in Varying Load Conditions

Passenger trains experience frequent acceleration and braking, requiring precise fuel tracking. AIC’s fuel flow meter for trains helps operators measure fuel consumption at different load levels.

- Works with train fuel monitoring systems for real-time tracking

- Ideal for optimizing fuel efficiency in stop-and-go rail operations

- Helps railway companies reduce fuel costs and emissions

For Freight Trains: Maximizing Fuel Savings on Long Routes

Freight trains operate under high-load conditions, making railway fuel management system integration essential for cost-effective operations.

- Enables efficient fuel tracking over long distances

- Provides real-time insights into fuel performance

- Works with diesel locomotive meter setups for better fuel control

AIC’s Cost-Effective Fuel Measurement Technology

AIC’s diesel train fuel flow meters require only a single-line measurement, making them more precise and cost-efficient than traditional dual-meter systems. This ensures accurate railway fuel meter readings while reducing maintenance costs.

Discover the Best Railway Fuel Monitoring Solutions

Our fuel flow meter for railway applications provide unmatched accuracy, durability, and efficiency. Contact us today to explore the best fuel monitoring solution for your railway operations!